May Wes – Celebrating 50 Years of Service

“Thank You for Your Business. We Will Continue to Earn It.”

My father Tom Daggett wrote those words back in 2003 in his first letter to May Wes customers. The summer before, he had acquired May Wes as a division of our family’s new business, Pride Solutions, LLC.

Dad grew up in manufacturing and ran a successful second-generation metal fabrication business just down the road from May Wes. He recognized the company’s tremendous potential and was excited to begin the next chapter in May Wes’s storied history.

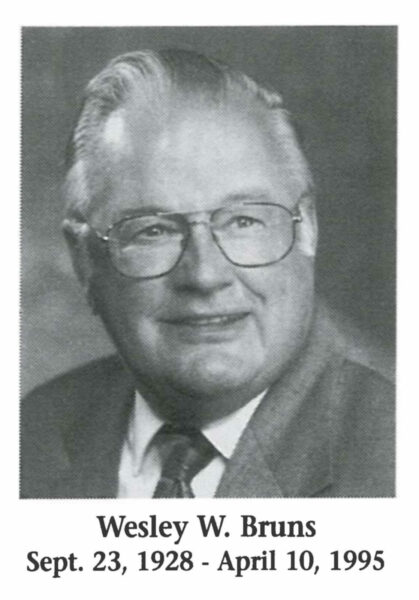

This year marks May Wes’s 50th Anniversary, an incredible achievement made possible thanks to our loyal customers, distributors and dealers, as well as our hardworking employees who have never lost sight of our founders Wesley and Mavis Bruns’ innovative spirit and commitment to listening to our customers.

Please read on to learn more about May Wes’s fascinating history and how a farming couple from the small town of Gibbon, Minnesota revolutionized agriculture.

Thank you again for your business. We will continue to earn it!

Jack Daggett, President

May Wes Manufacturing

Pride Solutions, LLC

May Wes – What’s In A Name?

In 1972, husband and wife Wesley and Mavis Bruns launched a small manufacturing business at their farm in Gibbon, Minnesota. Their new enterprise needed a name, so they combined their first names and, in a clever play on words, May Wes Manufacturing was born.

The Bruns foresaw an opportunity to help other farmers improve their operations with aftermarket products that increased efficiency and yields. Some of their first products included galvanized steel “Grain De-Viders” to guide grain into headers and “Gravity Flow Hoppers” that folded out for unloading.

From the beginning, Wesley Bruns was always on the lookout for the next great product that would transform modern agriculture.

Becoming ‘The Original Poly People’

After a few years in business, Wesley and Mavis incorporated plastics into their products and May Wes became known as “The Original Poly People.” They discovered that by attaching slick and durable UHMW poly to field equipment in areas of high stress where dirt and debris build up and where friction is the greatest, equipment lasted much longer and passed through fields with amazing ease.

Longtime employees recall stories of Wesley driving to the Twin Cities to fill his pickup truck with sheets of UHMW poly, and how, on one occasion, that slippery material suddenly went airborne on a busy interstate causing all sorts of mayhem. Today we bring it in by the semi-truckload.

Back in the day, May Wes employees hand cut the plastic material on a shear and bent it to make skid shoes for grain headers. In the mid-1980s the company installed a YAM CNC Mill to meet the growing demand for plastic skid shoes. In its first year of operation, with longtime employee Bill Templin at its helm, the YAM met the demand for 1,800 sets of skid shoes for the John Deere 200 Series grain head.

To this day, May Wes Premium Poly Skid Shoes remain the backbone of our company. The good old YAM worked hard for us for over 40 years. We augmented it with a Komo CNC router in 2003 and then replaced the YAM last year with a second Komo CNC router. We were fortunate to have Bill Templin on our team until 2014 when he retired at the age of 75. Sadly, Bill passed away in 2021 at the age of 82, and is greatly missed by us all.

‘The Original Stalk Stomper’

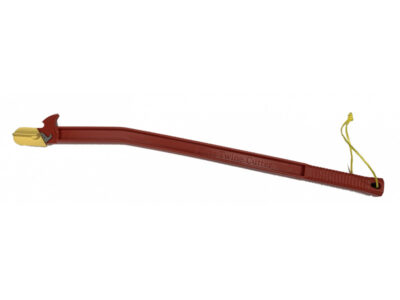

In 1983, May Wes again revolutionized the aftermarket ag industry with the introduction of the “Original Stalk Stomper.” This ingenious invention protected expensive combine tires from genetically modified cornstalks that had become as tough as nails.

Through the years, May Wes has continuously improved our No-Till Award-winning Stalk Stomper lineup with feedback and assistance from loyal customers. In 2018 we introduced our revolutionary G4 Stalk Stompers, which were recognized with the Best Game-Changing B2C Product at the Made in Minnesota Manufacturing Awards. We listened to corn growers and developed a lighter, easier to install and reposition Stalk Stomper featuring a durable compression molded shoe. Our G4 Stalk Stompers have been so well received that we now offer them for corn heads, planters and tractors. G4 Stalk Stompers are now our top-selling product.

May Wes Moves to Hutchinson, Minnesota

After Wesley Bruns passed away in 1995 at the age of 66, his sons Mark and Steve Bruns took over the family business. By 1997, May Wes had outgrown is space on the farm, and the company was relocated to our present facility in Hutchinson, Minnesota. Compression molding presses were added to grow the company’s capabilities. In the early 1990s, May Wes began molding C&A Pro snowmobile skis for snowmobile racing legend Dale Cormican. Today most professional snowmobilers run C&A Pro skis, including Levi LaVallee and four-time Snocross champion Elias Ishoel.

2002 – The Daggett Family Acquires May Wes

In 2002, Tom Daggett acquired May Wes and established Pride Solutions, LLC, under which we operate four divisions including May Wes, C&A Pro, Pride Engineered Plastics and Pride Assembly. Tom transformed May Wes’s business operation, utilizing the experience he gained as the second generation to run his family’s nearby metal fabrication business, Hutchinson Manufacturing. He introduced a number of organizational and strategic changes, improved inventory management processes, and made major investments in new manufacturing equipment. Under his leadership, May Wes secured its enviable marketing presence and became one of the first in our industry to embrace e-commerce.

2016-Today – The Next Generation of May Wes

In 2016, Tom’s son Jack Daggett became president of May Wes and Pride Solutions, LLC. Jack had worked on the company’s production floor from high school through his college years, gaining hands-on knowledge of its production processes. In 2013, he became Operations Manager and helped improve the company’s planning processes with an engineered approach to specifications and purchasing – a process that has helped us thrive during the pandemic despite many supply-chain challenges.

Under Jack’s leadership, Pride Solutions and May Wes adopted the Entrepreneurial Operating System®, putting the company on a solid growth trajectory. The company has introduced numerous new products in recent years, including its ever expanding G4 Stalk Stomper and skid shoe product lines, 5 Finger Quick Tines, poly pickup bands, and much more. Jack has continued investing in the company, acquiring its first robot-assisted CNC lathe and second CNC router. This spring we broke ground on a major addition that will double the size of our production facility.

“FarmTubers” Introduce May Wes to a New Era of Farmers

May Wes’s marketing presence continues to lead the industry. In 2018, we partnered with a rising YouTube star named Zach Johnson, the Minnesota Millennial Farmer, who introduced May Wes to a new generation of farmers around the world. This led to a complete transformation of our marketing program, and we now work with numerous FarmTubers and social media influencers including Larson Farms, Welker Farms, Brian’s Farming Videos, Stanley “The Dirt Monkey” Genadek, FastAg Montana, Finstad Skidloader and Snow Removal Service, and Northern Chill. We’ve even become YouTubers and social media influencers ourselves! We welcome you to become part of our story by tagging us @maywesmanufacturing.

As Always, We Remain – “Field Tested, Farmer Approved.”

May Wes has come a long way in the past 50 years, but one thing will never change. We remain devoted to Wesley and Mavis Bruns’ spirit of innovation and commitment to listening to our customers. We can’t say it enough: Thank you for your business. We will continue to earn it!

Original location at Bruns Farm in Gibbon, Minnesota.

Wesley and Mavis Bruns

Wesley Bruns founded May Wes with his wife Mavis.

“The Original Stalk Stomper.”

May Wes manufacturing facility in Hutchinson, Minnesota.

The Minnesota Millennial Farmer and Eric Bates shoot “Baling Hay” video in 2020.

A Salute to Our Long-Term Employees

Jeff Hennen, May Wes Shipping and Receiving

Jason Templin, Fabrication

Connie Lingbeek, Purchasing & Planning

Angie Macik, Accounting & HR

You know you’re doing something right as a business when your employees don’t want to leave. We currently have 38 employees and 25% of them have been with the company for more 10 years!

Jason Templin – 32 years

Jeff Hennen – 24 years

Connie Lingbeek – 20 years

Angie Macik – 17 years

Kent Welte -14 years

Chuck Boettcher -12 years

Anthony Whaylen – 11 years

Dave Elness = 11 Years

Ben Wick = 10 years

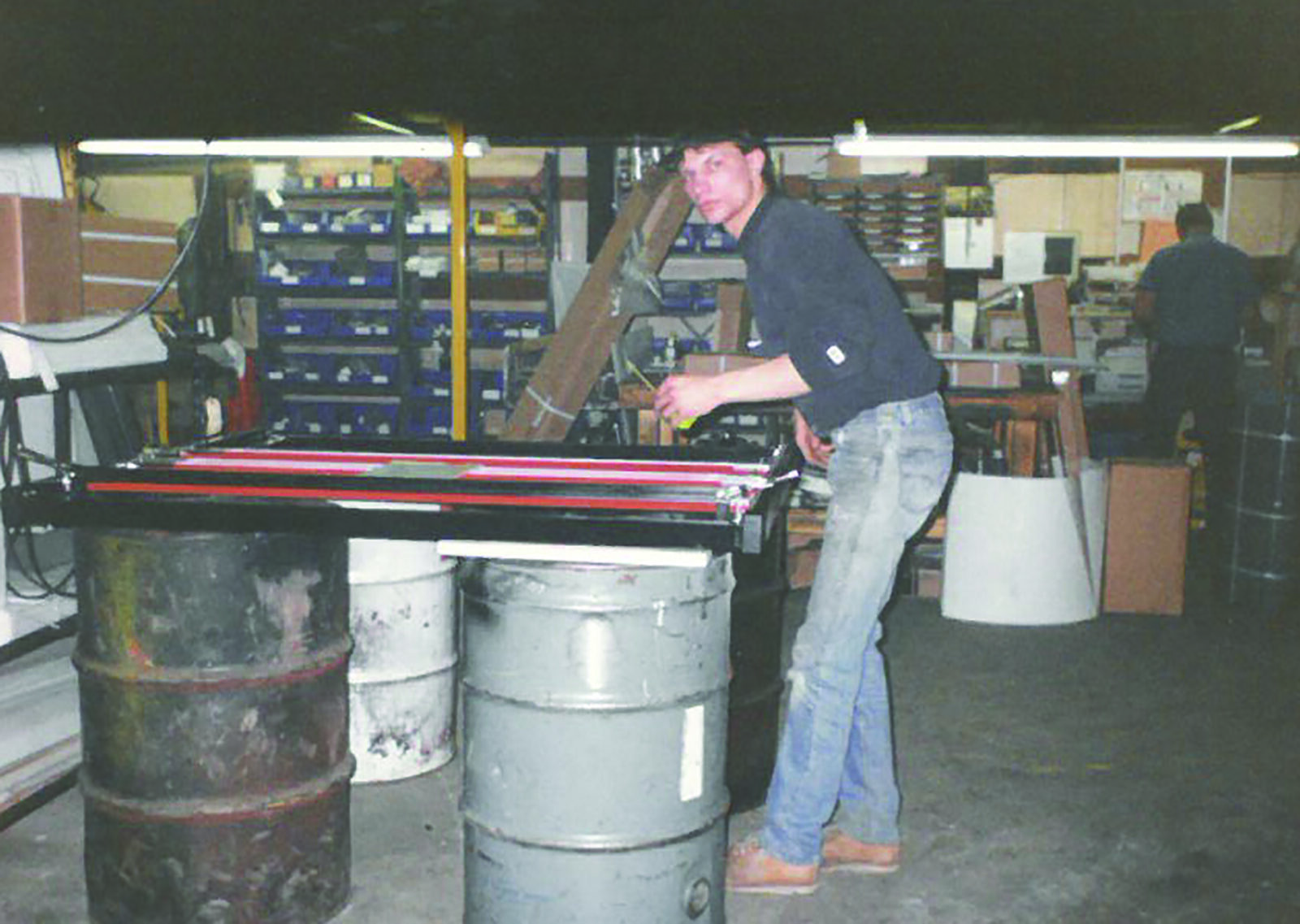

Jason Templin – 32 Years

Jason Templin, a distant cousin of Bill’s, is our current longest-term employee. He started with the company in 1990, working part time after school to earn money to buy an Arctic Cat EXT 580 snowmobile. He’s worked here ever since and has bought many more snowmobiles over the years. Jason now leads the May Wes fabrication department. He doesn’t miss the old YAM, but he said it got the job done.

“I’m content,” said Jason. “I like the people I work with and I like what I do.”

Jeff Hennen – 24 Years

Jeff has been with May Wes since 1998. He runs our very busy shipping department, which last year processed 12,614 shipments.

“I’ve stayed here because I like the people that I work with,” Jeff said. “The management is very accommodating and listens to what you have to say and always has an open door policy.”

Connie Lingbeek – 20 Years

Connie has been with May Wes and Pride Solutions since 2002. She is our Purchaser/Planner, and makes sure we have the parts and materials to get product out the door, a task that’s no small challenge these days.

“We have a great team here at Pride Solutions,” Connie said. “The willingness to work together to achieve a goal is second to none. Every day is different. There are always new tasks and challenges to conquer.”

Connie will never forget her first two days at May Wes:

“My first two days were not in the office, but at a local farm show,” she recalled. Talk about being thrown into a lion’s den. Talking with the farmers on what they like or suggestions for the future was a great and fast learning experience about our products. Being a farmer’s daughter did help. This truly set the stage for a fun and interesting adventure here at Pride.”

Angie Macik – 17 Years

Angie serves dual roles as accounting and HR manager for all divisions of Pride Solutions, including May Wes.

“I enjoy my job and the people I work with,” Angie said. “I like the diversity of my job. There is always something new. The employees with their hard work and dedication have really grown May Wes to what it is today.”

May Wes – A Tradition of Innovation

We’ve been introducing new products nearly every year since 1972!

1972 – Mavis and Wesley Bruns start up May Wes Manufacturing at their Farm in Gibbon, Minnesota

– Row Dividers

-Gravity Box Folding Hopper

1976 – UHMW Poly Skid Shoes

1980 – Moldboard Covers

-Tractor Fender Guards

-Wesley Walker

1983 – “Original Stalk Stomper”

1983 – YAM CNC Installed

1984 – Chaff Spreaders

1985 – Slide-N-Drive Fifth Wheel Covers (Now Minimizer Slickplates)

1988 – May Wes distributes its first catalog

-Poly Tin Replacement

-Grain Elevator Paddles

-Chute Liners

1990 –Grain Header Carts

1991 – Feeder House Silencer

1991 – Poly Shank Protectors

1992 – Poly Chain Tighteners

1993 – Poly Cutting Edge

1993 – Retractable Poly Fingers

1995 – Wesley Bruns passes away

1996 – Compression molding added

1996 – Poly Closing Wheels

1996 – Molded Skid Shoes

1997 – May Wes moves to Hutchinson, MN

2000 – Poly Capped bolts

2002 – New Owner Tom Daggett forms Pride Solutions

2002 – Ear Savers and Snout Savers

2003 – Komo CNC router installed

2005 – Auger Floor Liners, Corn Savers

2007 – Corn Shields

2009 – Drawbar Savers

2010 – Tractor Stalk Stompers

2014 – Quick Disconnect 2 Stalk Stompers

2014 – Poly Pickup Bands

2015 – Row Dividers

2016 – Jack Daggett becomes president

2016 – May Wes becomes Exclusive Distributor for GVL Poly Snouts

2017 – Robot-assisted CNC lathe installed

2018 – G4 Stalk Stompers Introduced

2018 – May Wes partners with Minnesota Millennial Farmer

2019 – G4 Planter Stalk Stompers Introduced

2020 – Crop Shields/Trash Aprons for John Deere and Case IH corn heads

2020 – 5 Finger Quick Tines

2021 – G4 Tractor Stalk Stompers Introduced

2021 – Second Komo CNC Router Installed; original YAM retired

2022 – 50th Anniversary

2022 – Added Baleskiis® Baler Liners and Black Talon Rubber Molded Rake & Baler Teeth

2022 – Construction begins on 20,000 square foot addition.

Meet Tony Fast of Fast Ag Montana at National Farm Machinery Show 2024

We’re excited to see you at the National Farm Machinery Show Feb. 14-17 in Louisville, Kentucky. Be sure to stop by our booth 7971 to take advantage of our NFMS show specials and meet Tony Fast of Fast Ag Montana from 11 a.m.-1 p.m. Thursday, Feb. 15!

We’ve got all kinds of new products for you to check out this year, including Kernel Keeper, SeedRight Seed Plates, BundleDrop Soybean Plates, Mini Combine, Rubber Rake and Baler Teeth, Hay Knife, LockNLube, LockNFlate and much more. We’ve also added several makes and models to our popular G4 Stalk Stomper and UHMW Poly Skid Shoe product lines. Stop by our NFMS booth to learn how May Wes poly products can protect and extend the life of your farm equipment and increase your yields and profits.

TONY FAST MEET & GREET 11 A.M.-1 P.M. THURSDAY, FEB. 15

What’s New from May Wes in 2024

Installing Compression Molded UHMW Cutterbar Skid Shoes with Tony Fast

Reduce Corn Shelling with Kernel Keeper

Moving Trailers Easy Peasy with Skid Hitch

Collecting Crop Samples with Mini Combine

Installing Poly Pickup Bands and Rubber Teeth on a Hay Baler

Winter Maintenance Projects to Help Farmers Prepare for Spring Planting, Next Year’s Harvest

The crops are out, the fields are tilled, and hopefully you’ve had a well-earned rest. Now it’s time to head out to the shop and get started on your winter maintenance projects.

Winter’s the perfect time to complete the projects you couldn’t get to last summer, but can’t afford to put off any longer. As Dad and Grandpa probably told you, “Benjamin Franklin had it right. An ounce of prevention is worth a pound of cure.”

To help you get started on your checklist, we put together a list of maintenance projects ideally suited for winter “downtime.”

Auger Wearshoes and UHMW Tube Liners for combines & grain carts

Whether you have a new auger you are looking to protect or an old auger that is showing its wear, you can greatly extend auger life by bolting on May Wes auger wearshoes. For complete protection, install May Wes UHMW tube liners. Wearshoes bolt on using UHMW poly capped bolts. We have many in stock and ready to ship, but also can make custom wearshoes and have them shipped to you within a couple of weeks. Order now so you are ready to go for spring planting.

Hay Baler Maintenance Projects

That first cut will be here faster than you know, especially with this mild winter. Now’s the perfect time to install a BaleSkiis Baler liner, replace your rattily metal pick up bands with whisper quiet poly pickup bands, and install Black Talon rubber coated baler teeth. A BaleSkiis liner will take the better part of a day to install, something you will be happy you did over the winter instead of scrambling to fit it in between planting, cutting and baling. While you’re at it, outfit your baler with rubber coated baler teeth and new poly pickup bands. Your baler will run so efficiently you’ll wonder why you didn’t do it sooner.

Corn Head Winter Maintenance Projects for Corn Growers

You saw our Kernel Keepers on the Millennial Farmer last fall, but probably didn’t have time to install them. Kernel Keepers will dramatically increase your yields and are well worth the time to install. Stop feeding the deer and feed your family instead. Order Kernel Keepers today. We make the Kernel Keeper UHMW rails right here in the U.S.A. in our Hutchinson, Minnesota plastic CNC routing and fabrication shop.

Corn head troughs often get neglected, but sparing a day to install a May Wes UHMW corn head auger trough liner will reap huge rewards come harvest by preventing grain from falling through rust holes. May Wes Corn Head auger trough liners are much easier to install than replacing the OEM metal liners. You simply bolt and rivet into place. We make them in our Minnesota plastic fabrication shop.

Our world famous G4 Stalk Stompers are not just for combines. Install them on your planter and tractor to protect all your tires! Don’t wait until August to install your corn head G4 Stalk Stompers. Get them now to avoid the longer shipping lead times of the busy harvest season. G4 Stalk Stompers are a great investment. They will save you thousands of dollars on tires and tracks.

Combine winter maintenance projects

Grain Tank & Auger Bed Liners

These are both big jobs, but they will reap HUGE rewards. Take the time this winter to finally line your grain tank and auger bed with May Wes poly. The UHMW liners simply rivet into place. We make them in our Minnesota plastic shop.

Grain Head Winter Maintenance Projects to Increase Yields and Resale value

Now’s a great time to give your grain head a good look over so it’s ready to go next harvest, or will command a better price if it’s time to upgrade your header. May Wes offers numerous poly products to protect your grain platform and increase efficiency and yields.

Get your grain platform ready for next harvest by completing the following repairs this winter:

UHMW Poly Skid Shoes – Replace those worn out skid shoes with premium UHMW poly skid shoes from May Wes. Don’t forget we now have compression molded UHMW cutterbar skid shoes available that are better than OEM at a fraction of the price. May Wes UHMW skid shoes are proudly made in U.S.A. in our plastic CNC routing and fabrication shop and compression molding shop.

Grain Head Auger Trough Liner – If your grain head liner is starting to look like an old rust bucket, get it lined right away with UHMW poly and stop pouring grain back onto the field. This project only takes a few hours and is easy to do by yourself or with a helper. Our UHMW liners can be used over holes as big as softballs. Check out the Larson Farms video to see how easy it is to get this job done.

Poly Fingers – Break a metal finger and you’ll be sorry if gets into your threshing system. Now’s a great time to replace your grain drum fingers with Poly Retractable Fingers from May Wes. You can replace just the broken metal fingers or play it safe and replace all the metal fingers with poly fingers. While you’re at, repair your dented grain head auger drum using a Tru-Tube Auger Straightener. It works way better than a torch and crowbar.

How to Order AG Parts for Your Winter Maintenance on the Farm

You can order all these products from your local May Wes dealer or directly from this website. We’d be happy to mail you a free catalog so you can check out our thousands of poly products to help increase your farm’s profits.

15 Holiday Gift Ideas for Farmers from May Wes Manufacturing

As the holiday season approaches, finding the perfect Christmas gift for the farmers in your life can be a rewarding challenge. This year, consider innovative and durable solutions from May Wes Manufacturing, an American pioneer in aftermarket poly wear products for agricultural equipment. With a commitment to enhancing the performance and longevity of farming machinery, May Wes offers a diverse range of high quality products that make thoughtful and practical gifts. From air filter blasters to poly cutting edges, this article will explore 15 Christmas gift ideas for the farmer in your life, all available from May Wes Manufacturing.

-

Air Filter Blaster Complete Kit with 6” Rotor Included:

This is one of the only tools you’ll ever buy that will pay for itself the first day you have it. The leading cause of fuel consumption, engine damage and turbo damage is air filters. May Wes provides an efficient solution with the Air Filter Blaster Complete Kit. This innovative tool cleans air filters with an even distribution of air, ensuring optimal engine performance and longevity. We also offer additional rotor sizes from 3” up to 9” to accommodate just about any filter on the market.

Kit price: $299

Shop Air Filter Blaster

-

Skid Loader Hitch Receiver:

For farmers with skid loaders, a Skid Hitch is a versatile and practical gift. Move trailers around the farmyard quickly and easily with this handy skid loader attachment. The Skid Hitch is a universal attachment that will fit on every model and make of skid loader. Lightweight and easy to install and remove, it fits right in your truck toolbox! 2” standard receiver and ball hitch not included.

Price: $185

Shop Skid Hitch

-

Snoot Boots for Corn Heads:

The highly visible Snoot Boots from May Wes make it easier for you to find row centers in adverse weather conditions. The slick surface also aids in preventing trash build-up. These Snoot Boots easily slide on and snap over your existing points. Available for Case IH, New Holland and John Deere corn heads.

Price: $13.25 – $17.55 each

Shop Snoot Boots

-

Snout Savers for Corn Heads:

Extend the life of corn head snouts with May Wes’ Snout Savers. The curved design lifts the point of the snout just off the ground, preventing the operator from driving that tip into the dirt and crumpling the snout. Hardware is included.

Price: $26 each

Shop Snout Savers

-

Hay Knife for Removing Bale Wraps:

Make the task of removing bale wraps easier with May Wes’ Hay Knife. This durable tool cuts twine, mesh, plastic wrap, feed bags and more. The Hay Knife’s 30” length and hooked end makes grabbing material quick and easy.

Price: $30 each

Shop Hay Knife

-

Poly Pickup Bands for Hay Forage:

Upgrade your hay baler with May Wes’ Poly Pickup Bands. These durable poly bands maintain their shape and will not bend or break when struck by objects in the field. Plus, they eliminate that metal-on-metal clatter, making the cab ride much quieter and more comfortable. You can replace just the broken metal pickup bands or outfit your entire baler with Poly Pickup Bands.

Price: $22.50 – $29.95 each (varies by model)

Shop Poly Pickup Bands

-

Draw Bar Savers for Tractors:

Pulling implements can wear out your tractor’s drawbar. Protect your draw bars and hitches from metal-on-metal friction with May Wes’ Draw Bar Savers. Made from slick UHMW poly known for its durability and wear resistance, extend the life of your tractor’s drawbar for as little as $6.30.

Price: $6.30 – $20.00 each

Shop Draw Bar Savers

-

UHMW Poly Cutting Edges for Buckets and Plows:

Protect concrete and asphalt from plow damage with a Poly Cutting Edge from May Wes. Our Poly Cutting Edges are custom cut to fit any model of snowplow blade, skid loader bucket, truck or ATV plow and more. Made from slick and durable UHMW, Poly Cutting Edges ensure effective snow removal without damaging smooth paved surfaces, making it an ideal gift for winter.

Starting at $2.00/running inch

Shop Poly Cutting Edges

-

5-Finger Quick Tines:

When dealing with short crops and drought years, the 5-Finger Quick Tines from May Wes will feed more bushels of crop into your combine. Our quick-attach design slips over the existing finger quickly and securely, no tools or hardware needed for installation. Designed for use in soybeans, wheat, chickpeas, lupins and flax.

10-pack kit: $64.20 – $76.40 (varies by model)

Shop 5-Finger Quick Tines

-

Retractable Poly Fingers for Grain Heads:

Enhance the efficiency of grain harvesting with May Wes’ Retractable Poly Fingers. These durable and flexible fingers improve crop flow and reduce repair costs. Broken metal fingers can do costly damage to the drum and thresher system. The advantage poly fingers have over metal is when they eventually break, the poly will disintegrate as it passes through the combine and will not damage the internal working parts like rotors and cylinders.

12-pack kit: $191 – $215 (varies by model)

Shop Poly Retractable Fingers

-

SeedRight Seed Plates for Planting:

Transform your planter to plant cover crops and small grains with SeedRight’s patented seed plates available from May Wes. Expand your planter’s capability and get more use out of that expensive piece of equipment. SeedRight seed plates are available for John Deere, Kinze and Precision Planting planters.

Price: $35 – $54 each

Shop SeedRight Seed Plates

-

Kernel Keeper for Corn Heads:

May Wes offers the Kernel Keeper to help farmers save more kernels during corn harvest. The Kernel Keeper rails reduce shelling by cushioning ears on impact, and the included brushes guide loose kernels into the auger bed. Priced at $195 per row, save over $500 per row vs the competing products on the market. This gift is a thoughtful investment in a farmer’s long-term success.

Kit Price: $195 per row

Shop Kernel Keeper

-

DU-HA Storage Devices:

Practical storage solutions are always appreciated on the farm. DU-HA Storage Devices provide secure storage options for tools and equipment in a single easy-access, out-of-sight place under the seat of your truck. DU-HAs are made for the make and model of your truck so the fit is perfect.

Price: $200 – $400 (varies by model)

Shop DU-HA Storage Devices

-

Molded Cutterbar Skid Shoes for Case IH, New Holland and MacDon Drapers:

May Wes’ Cutterbar Skid Shoes are manufactured from slick and durable 3/8” thick UHMW poly. These durable skid shoes reduce friction and prevent premature wear, ensuring a longer lifespan for your cutterbar. Measuring 6” x 6.5”, May Wes’ Cutterbar Skid Shoes are a cost effective replacement for the OEM part. Compatible with Case IH, New Holland and MacDon Drapers.

10-pack price: $105

Shop Cutterbar Skid Shoes

-

Rapid Drain Filter Tile Inlet for Planting:

May Wes’ Rapid Drain Filter Tile Inlet is a game-changer for field drainage. Its patented no-clog design allows for maximum tile flow at minimum depths, ensuring optimal soil conditions for crops. The design allows for a more uniform free flow of water into the tile and is self-cleaning. High visibility yellow can be easily seen as a marker for underground location.

Price: $43 – $50 each

Shop Rapid Drain Filter

This Christmas, give the gift of innovation and durability to the farmers in your life with May Wes Manufacturing’s aftermarket poly wear products. From tools that increase efficiency to accessories that prolong the lifespan of equipment, May Wes has you covered. Choose a gift from this list, and you’ll not only make the holiday season special but also contribute to the success and longevity of the farming operation. Happy holidays!

Prices listed in this article are subject to change. Prices are listed in USD and do not include freight charges.

Installing Snoot Boots on a John Deere C Series with Millennial Farmer

Eric Answers Frequently Asked Questions About Snowplow Poly Blades

Skid Hitch FAQ: How to Move Trailers with a Skidloader

Installing Cutterbar Skid Shoes with Fast Ag Montana

May Wes Black Friday Sale Nov. 22-27

Black Friday Special: Free Ground Shipping on Skid Hitch & Poly Retractable Fingers in Contiguous 48 States Nov. 22-27.

Use Promo Code: BLACKFRIDAY23

Skid Hitch Makes Moving Trailers with a Skidloader Easy Peasy

This handy attachment allows you to quickly add a standard 2″ trailer hitch receiver (not included) to your skid loader so you can move trailers around your farm yard with your skid steer. Lightweight and easy to install and remove, it will fit right in your truck toolbox! NOTE: 2″ standard receiver and ball hitch sold separately.

Bent and broken metal auger fingers can wreak havoc on your combine. Protect your combine from costly damage by replacing your grain head auger fingers with retractable poly fingers from May Wes. Poly fingers are less expensive than metal and are strong and resilient. If they do break, the poly will disintegrate as it passes through the combine and will not damage the threshing system. Order your poly fingers today so you’re not wishing you had tomorrow.

FAQ Answers Snowplow Operator Questions About UHMW Poly Cutting Edges

Snowplow operators, homeowners, farmers and ranchers have many questions about the slick and durable UHMW poly cutting edges (aka ploy blades) available from May Wes Manufacturing.

This FAQ about Poly Snowplow Blades answers the most common questions snowplow operators are asking. If you have additional questions, please give us a call at 1-800-788-6483.

What material are May Wes Poly Cutting Edges made from?

May Wes Poly Cutting Edges are manufactured from virgin UHMW Poly right here in our Hutchinson, Minnesota plastic fabrication shop. We do not use reground poly like many of our competitors. Our skilled plastic fabricators cut and drill them to your specification on our Komo CNC router. UHMW is the same slick and durable plastic we use to manufacture May Wes premium skid shoes for grain heads and G4 Stalk Stompers. It is also used to make C&A Pro high performance snowmobile skis used by professional snocross racers.

How long will a May Wes poly snowplow cutting edge last?

The life expectancy of your poly snowplow cutting edge will depend on how much you use it, the thickness of your poly blade, the surface you are plowing and what you are plowing. The thicker the blade, the longer it will last. Our poly blades are used by DOTs, cities, commercial plowing services, homeowners, farmers and ranchers. We used the poly blade on our shop truck for two winters before flipping it over to double its life. Our parking lot is part asphalt and part gravel (Note: poly cutting edges are recommended for paved surfaces only; gravel will wear them out faster.). Unless you specify otherwise, we drill the holes down the center so you can flip the UHMW blade over when the first side wears out.

What materials can you plow with a Poly Cutting Edge?

Most of our customers use them to plow snow, but we’ve had customers use them to plow manure, hay and straw, fertilizer and other materials.

Vertical snowplow cutting edges are straight and the holes are drilled through.

Does May Wes have a UHMW Poly Cutting Edge available for my make and model of bucket or plow?

We make all of our cutting edges custom to your specification and can make cutting edges for just about every snowplow, bucket, pusher or box blade out there. We just need to get a few measurements from you.

What is the difference between a vertical snowplow and a horizontal snowplow?

Horizontal plows are what you see on tractor or skid steer buckets. The cutting edge runs horizontally on the ground. For horizontal applications, we will bevel cut the cutting edge and countersink the holes. Vertical plows are what you see on snow pushers, pickup or ATV plows, box blades and the back of snow pushers. They are cut with straight edges and holes are drilled through .

Can May Wes make skid shoes for the bottoms of my snow pusher?

Yes. We can custom make you UHMW skid shoes for your snow pusher, just like we did for Larson Farms!

Horizontal cutting edges are beveled and the holes are counter sunk.

What measurements does May Wes need to make my custom snowplow cutting edge?

We will need to know the length of the plow, plus which thickness and width you would like. We also need your hole measurements if you would like us to drill the holes for you. Measure your holes from the edge of the plow to the center of each hole. Measure twice as custom poly cutting edges cannot be returned. It can be helpful to provide a drawing if you have stacked hole patterns. Please specify if your holes need to be drilled off center, otherwise we will drill them down the center. Please watch this video for measurement instructions.

What thickness of snowplow cutting edge do I need?

We offer 3/4″, 1″ and 1 1/2″ UHMW poly cutting edges. We recommend using the thicker poly blades for commercial and farm use. The thinner blades are more suitable for plowing homeowner driveways. The thicker the blade, the longer it will last.

How wide of a cutting edge should I get for my snowplow?

Generally speaking, get the same width and length as your metal snowplow cutting edge, but if you have space for a wider poly blade, go for it as it will last longer.

How far back are the bevels cut on May Wes horizontal poly cutting edges?

We CNC cut the the bevels at a 45 degree angle. On a 3/4″ poly blade, the bevel starts 3/8″ from the edge. On a 1″ thick cutting edge, the bevel starts at 5/8″. On a 1 1/2″ cutting edge, the bevel starts at 1″ from the edge

How deep are the counterbore holes cut on May Wes horizontal poly cutting edges (aka poly blades)?

3/4″ thick cutting edges will have .45″ UHMW material left. 1″ and 1 1/2″ cutting edges will have .65″ UHMW material left.

How do I order a May Wes poly cutting edge?

You can order your May Wes poly blade through your local May Wes dealer, order online at www.maywes.com or give us a call at 1-800-788-6483.

How long will it take to get my custom May Wes poly cutting edge?

Our plastic fabricators can typically make your custom snowplow poly blade in a couple of business days. Please allow time for shipping. During the busy harvest season, our lead times can get extended.

How are May Wes poly blades shipped?

Poly cutting edges are normally shipped UPS or Spee-Dee, or you can pick them up at our shop in Hutchinson, Minnesota. Poly blades longer than 94″ that cannot be seamed will be shipped LTL freight or you can pick them up.

Have more questions? Please call us at 1-800-788-6483.