Meet Tony Fast of Fast Ag Montana at National Farm Machinery Show 2024

We’re excited to see you at the National Farm Machinery Show Feb. 14-17 in Louisville, Kentucky. Be sure to stop by our booth 7971 to take advantage of our NFMS show specials and meet Tony Fast of Fast Ag Montana from 11 a.m.-1 p.m. Thursday, Feb. 15!

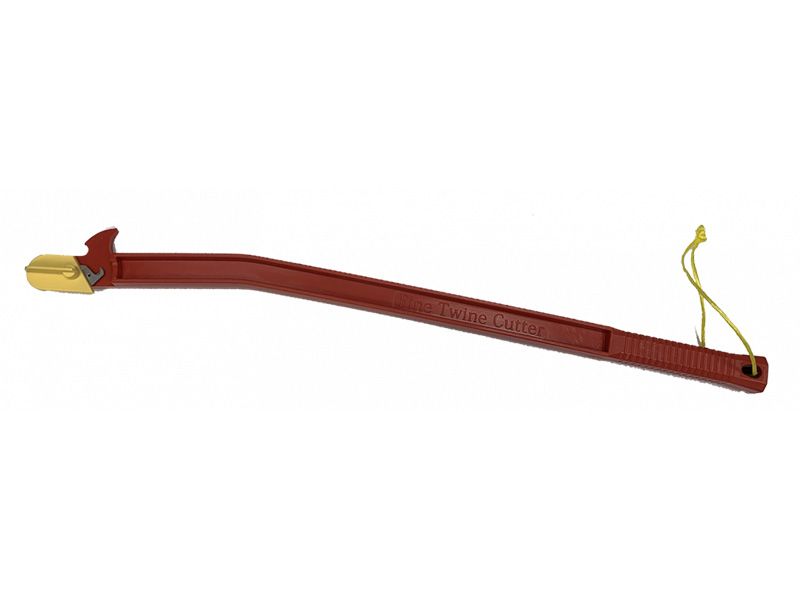

We’ve got all kinds of new products for you to check out this year, including Kernel Keeper, SeedRight Seed Plates, BundleDrop Soybean Plates, Mini Combine, Rubber Rake and Baler Teeth, Hay Knife, LockNLube, LockNFlate and much more. We’ve also added several makes and models to our popular G4 Stalk Stomper and UHMW Poly Skid Shoe product lines. Stop by our NFMS booth to learn how May Wes poly products can protect and extend the life of your farm equipment and increase your yields and profits.

TONY FAST MEET & GREET 11 A.M.-1 P.M. THURSDAY, FEB. 15

A long winter of snowplowing can leave your driveway and parking lot scuffed and scratched. Avoid this expensive and unsightly snow removal damage with a May Wes

A long winter of snowplowing can leave your driveway and parking lot scuffed and scratched. Avoid this expensive and unsightly snow removal damage with a May Wes  May Wes UHMW Poly Cutting edges are available in 3/4″, 1″ and 1 1/2″ thicknesses and 4″, 6″ and 8″ widths. Lengths are cut to your specification. Cutting edges that are 94″ or longer are normally cut in half to reduce shipping costs. If you require a full length seamless cutting edge longer than 94″, we can manufacture them up to 119″ long. LTL freight shipping rates will apply for poly blades 94″ or longer, or you can pick them up at our plastic fabrication shop in Hutchinson, Minnesota. In addition to poly cutting edges, we also manufacture

May Wes UHMW Poly Cutting edges are available in 3/4″, 1″ and 1 1/2″ thicknesses and 4″, 6″ and 8″ widths. Lengths are cut to your specification. Cutting edges that are 94″ or longer are normally cut in half to reduce shipping costs. If you require a full length seamless cutting edge longer than 94″, we can manufacture them up to 119″ long. LTL freight shipping rates will apply for poly blades 94″ or longer, or you can pick them up at our plastic fabrication shop in Hutchinson, Minnesota. In addition to poly cutting edges, we also manufacture